cassava bags manufacturing process

Cassava Bags Manufacturing Process - DesaignHandbags

Cassava Bags Manufacturing Process - DesaignHandbagsWe use cookies to improve your experience on our website. By using our website you agree to all cookies according to our update. This plastic bag is 100% biodegradable These are the best universities in the world in 2021A year in the pandemic: 3 things we have learned about the planetCOVID-19: What you need to know about the coronavirus pandemic on March 16A company in Indonesia has created a plastic bag so ecological that you can eat it. It is made of mandium, the vegetable root that is a basic element in the diets of many in Africa, Latin America and Asia, but that can also be used in manufacturing. The company, based in Bali, has created a bag that they say as plastic, but is completely degradable and compostable. It also dissolves in the water, so if the animals eat it, it will not cause any damage. They say it's so safe, in fact, that humans could even swallow it. Indonesia has a massive problem of plastic pollution. The unveiled plastic is drowning its rivers and drowning its virgin beaches. "Our country is drowning in plastic," Chief Green Officer at the company. The problem has become so acute that it helps clear the waste. But it's a fight uphill. As they clean the waste, it appears more. The Problem of Global Plastics The World Plastic ProblemAthletic pollution is a problem worldwide. Each year, plastics find their way to the ocean, the equivalent of dumping the content of a garbage truck in the ocean every minute. Marine life and birds die for eating or getting caught up in it. Plastic also breaks down into the ocean, becoming small enough to enter the food chain. is collected for recycling, while most plastic packaging is used only once. In addition, 95% of the value of plastic packaging material, which is worth between $80 billion and $120 billion annually, is lost to the economy. It's a massive problem, but it has driven many to try to find a solution. The new plastic economyThe new plastic economy, an initiative of the , brings together key actors, including innovators and manufacturers, to rethink and redesign the future of plastics, starting with packaging. The basic idea is to convert the linear plastic economy - use it and discard it - into a circular, where plastic can be reused or recycled. One of the Foundation's main projects is a . The prize is divided into two parts, The Circular Design Challenge, which invites ideas on how to change the way packaging is designed, and the Materials Challenge Circular, which invites ideas on how to replace plastic with other materials. New Plastic SolutionsNew Plastic SolutionsAmong the winners of the design challenge is one that tries to solve the coffee problem. More than 100 billion cups of disposable coffee are sold worldwide every year, but are barely recycled. The US-based start-up has designed a disposable paper cup with an origami technique that eliminates the need for a plastic cap. It is made of 100% compostable material. Among the winners of the material challenge is the Finnish VTT Technical Research Centre, with packaging that looks and feels like plastic, but it is made of wood. The substance is a compostable multilayer material from agricultural and forest by-products, which could be used to package products such as muesli, nuts and cheese. In theory, this type of packaging of the current plastic barrier film market. Plastic waste obstructing the riverways of Jakarta is the inspiration for the design of material challenge by . The company has designed a solution to unique-purpose food wrappers, such as salsa wrappers and food wrappers, which are so small that they escape the collection and end up on beaches, rivers or oceans. It has made food wraps and wraps of an algae material that can be dissolved in water or eaten. It can even feed plants - and contains vitamins and minerals, so it is a natural fertilizer for plants. The winners of the innovation prize join a 12-month accelerator program, in collaboration with , working with experts to make their marketable innovations on a scale. However, while the winning innovations represent the kind of solutions we need to build a functioning plastic system, these entrepreneurs cannot lead the transition alone. Companies, policymakers and investors must also make clear commitments and collaborate in a circular economy for plastics. Have you read? The articles of the World Economic Forum can be reissued according to it, and according to ours. , Senior Writer, Format Content The views expressed in this article are those of the author alone and not the World Economic Forum. Subscribe for updates More Future Consumption 4 questions you need to ask your post-COVID-19 supply chain The COVID-19 pandemic exposed the fragility of our global supply chains. Post-pandemic, this is how companies can handle difficult strategic decisions. To help your business in the future, take into account these 4 stepsTruly sustainable companies consider the planet and benefits. These companies have developed practices to help them survive in the long term. What can consumers do to help resolve the climate change crisis? I created a class to teach zero waste. It became much more Why people are choosing to rent their Christmas trees These toy manufacturers are giving their products a COVID-19 twist for ChristmasSubscribe for updates

Cassava Bags Manufacturing Process - DesaignHandbags

Cassava Bags Manufacturing Process - DesaignHandbags

Cassava Bags Manufacturing Process - DesaignHandbags

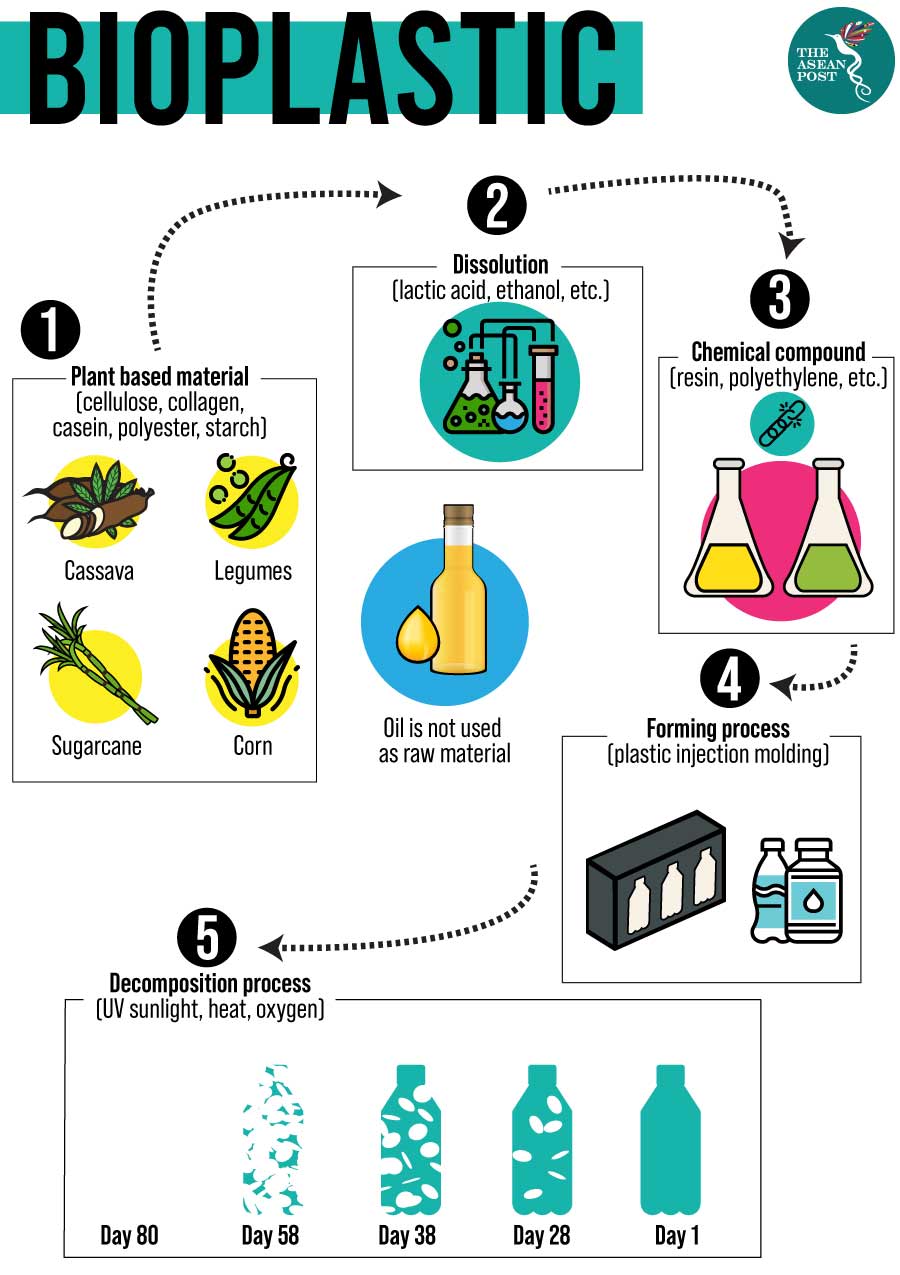

Plant-based plastics can make a difference | The ASEAN Post

Biodegradable environment friendly cassava bag - YouTube

Cassava Bags Manufacturing Process - DesaignHandbags

Cassava Bags Manufacturing Process - DesaignHandbags

Cassava Bags Manufacturing Process - DesaignHandbags

Cassava Eco friendly Bags | Ideal Replacement to Toxic Plastic Bags | Ecomaniac

Madagascar produces environmentally-friendly cassava bags - YouTube

Cassava Bags Manufacturing Process - DesaignHandbags

Cassava Eco friendly Bags | Ideal Replacement to Toxic Plastic Bags

This Cassava-Based Plastic Bag Alternative is Biodegradable Even Edible | Biodegradable products, Plastic bag, Biodegradable plastic bags

Plastic' bags made from potato and tapioca - TheCivilEngineer.org

Automatic Cassava Starch Bag Making Machine, Rs 1700000 /unit Sri Durgalakshmi Impex | ID: 19571362512

Cassava Bags Manufacturing Process - DesaignHandbags

This plastic bag is 100% biodegradable | World Economic Forum

This Cassava-Based Plastic Bag Alternative is Biodegradable, Even Edible - Core77

Could this Indonesian invention solve the world's plastic bag problem?

Cassava Bags Manufacturing Process - DesaignHandbags

Making Plastic Bags out of Bitter Cassava | Collecting and Exchange of Local Agricultural Content

A review of cassava in Asia with country case studies on Thailand and Viet Nam

Cassava Starch Bags Making Machine - DesaignHandbags

Man Creates Plastic Bags From Potato and Tapioca - Tech Explorist

How to make bio-degradable bags from cassava starch - Quora

This Company Makes Cassava-Based 'Plastic' Bags That Dissolve in Water! (VIDEO) | Biodegradable plastic bags, Plastic alternatives, Biodegradable plastic

China 25-50kg Per Bag Cassava Flour Packing Machine - China Flour Production Line, Cassava (garri) Processing Machines

How to make bio-degradable bags from cassava starch - Quora

Process flow chart for high quality cassava flour (Cassava Master Plan,... | Download Scientific Diagram

Cassava Eco friendly Bags | Ideal Replacement to Toxic Plastic Bags | Ecomaniac

How Green Are Those New Cassava Bags? - Legal Reader

Eco Friendly Compostable D2w Epi Cassava Corn Starch 100% Oxo Biodegradable Plastic Bag Wholesale - Buy Oxo Biodegradable Plastic Bag,Oxo Biodegradable Plastic Bag Wholesale,100% Oxo Biodegradable Plastic Bag Wholesale Product on Alibaba.com

THAI TAPIOCA STARCH ASSOCIATION

WAVE Startup Creates Emission-Free Bio Plastic Bags From Cassava That Dissolve In Water

Could this Indonesian invention solve the world's plastic bag problem?

China Bio Cassava Bag Custom Biodegradable Cornstarch Usable T Shirt Grocery Shopping Plastic Bags with Logo - China Plastic Bags, Biodegradable Plastic Bag

Making eco-friendly thermal cups and trays using cassava - YouTube

![PDF] Biodegradable plastics from cassava starch in Thailand | Semantic Scholar PDF] Biodegradable plastics from cassava starch in Thailand | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/4f7c0e6e5cee730b69f80f74c25e16b55b1a1f53/3-Figure1-1.png)

PDF] Biodegradable plastics from cassava starch in Thailand | Semantic Scholar

Plant-based, Home Compostable Bags | Telobag Singapore

How to make bio-degradable bags from cassava starch - Quora

Posting Komentar untuk "cassava bags manufacturing process"